I got interested in furniture design while still in design school. I took a furniture design class led by Brian Kimura, an established furniture design expert and then two others after graduation.

I think what interests me about furniture is that it is a discipline that can be interpreted on the level of art as well as design.

Also, unlike consumer electronics, I can design and build an entire piece myself, giving the creation experience consistency and simplicity.

I have collected here a series of sketches and photos of both finished and unfinished pieces that I have done over the years that chronicles my interest. I hope you enjoy them.

The first is a bent wood piece. I love bent wood furniture because it it can create forms that seem magical in their strength and lightness. They are also resource efficient and get their shape by additive manufacture of bending rather than reductive by cutting. Very little scrap is generated.

At first, I was going for an entire chair but this was a project I was determined to finish in a decent amount of time, so I simplified the design to a side chair which I dubbed Baryl.

Baryl starts with 1/16" American white ash veneer. This veneer is sliced, not sawed so no waste is generated to produce the flitches (log slices).

The slices were then glued and put into this custom form I built. The 6 thin wood veneers bend easily but become extremely strong and act as one once the special glue dries.

Each form produces 2 slats that were joined to create the chair as seen below. I created this shape with a very slight curvature on the top and sides so that I could test if there was any spring back over the years.After 10 years the curvature is still exactly as when I made it.

Baryl. The finished chair.

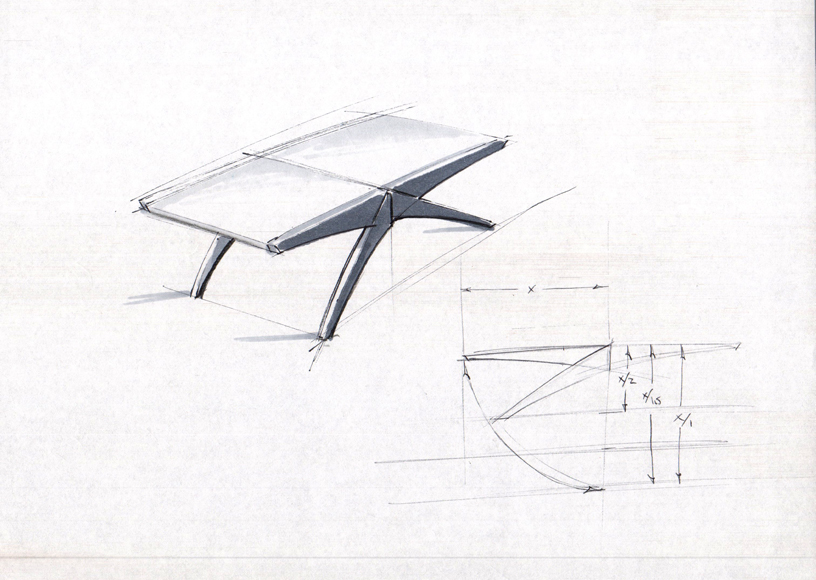

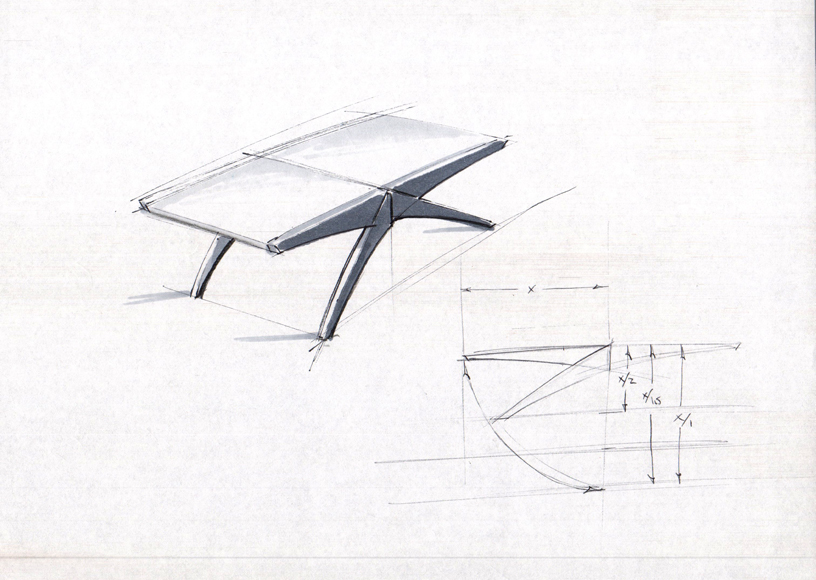

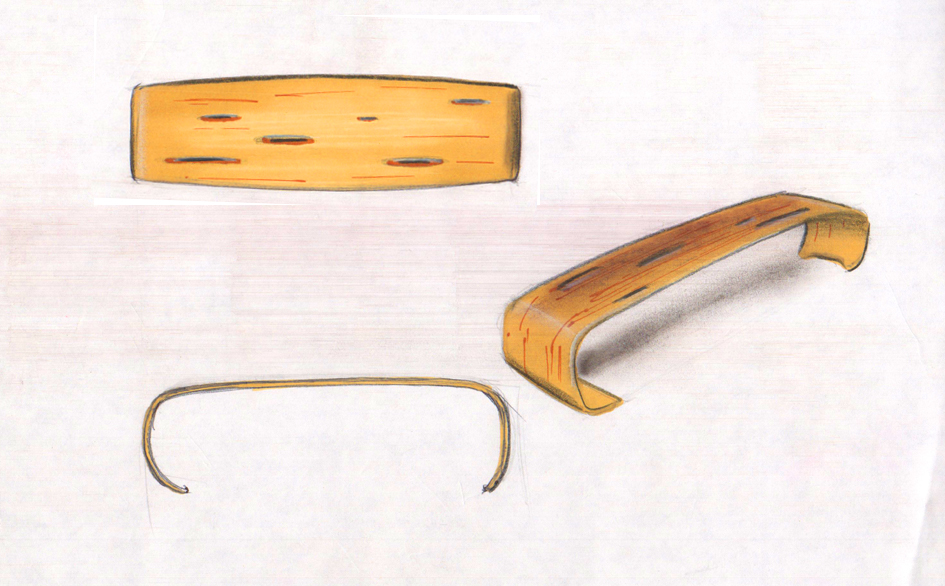

Side table concept. The idea here was to see how much action and form I could get from essentially flat pieces. It also pays homage to my love for mid-century furniture forms.

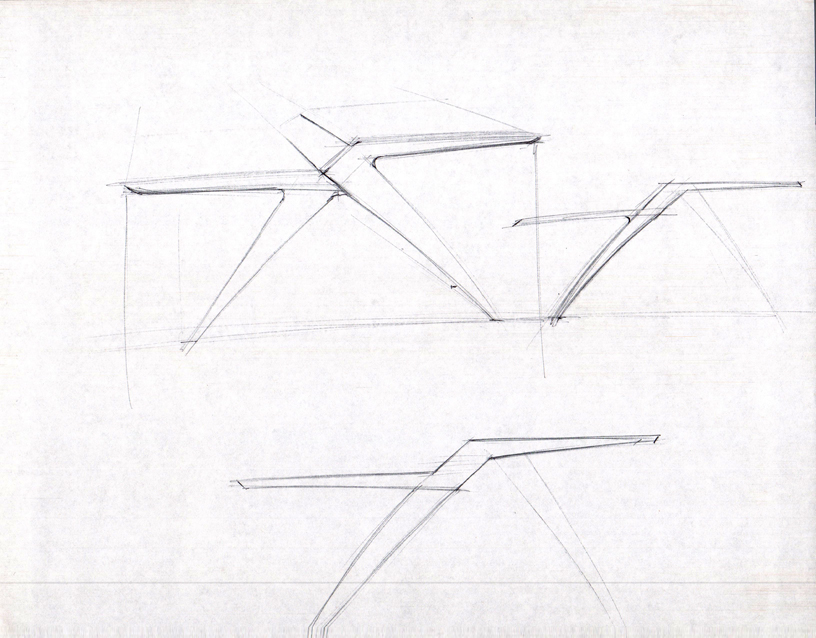

Slide table refinement using repeatable elements for efficient manufacture.

Machined sustainable mahogany

More Slide table refinement.

Machined sustainable mahogany

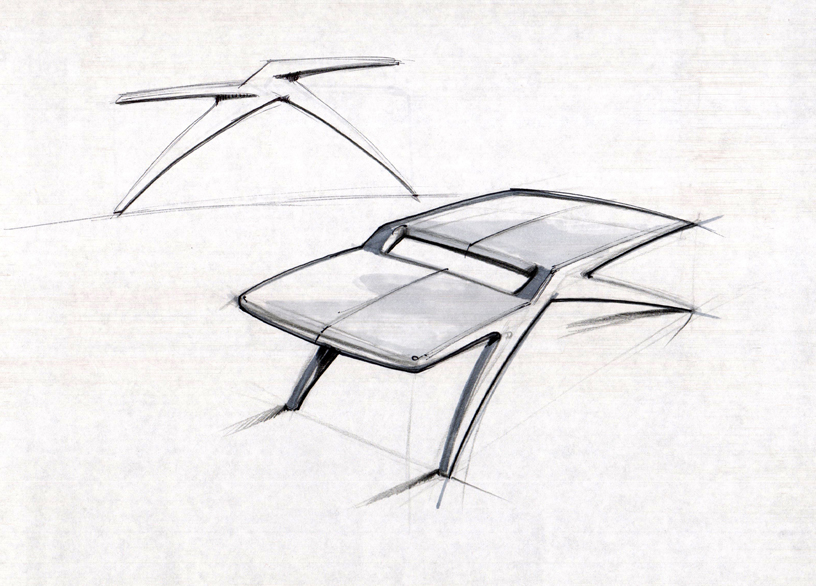

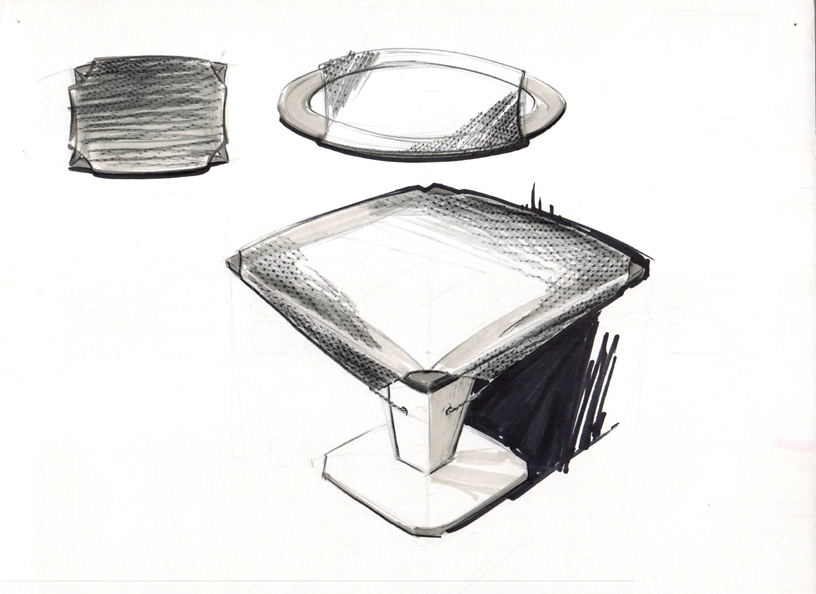

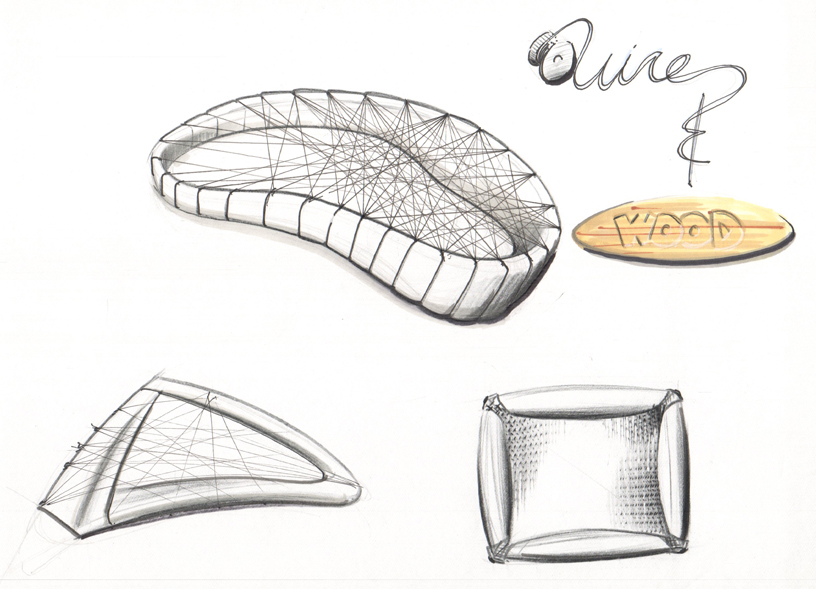

Stretched material table concept.

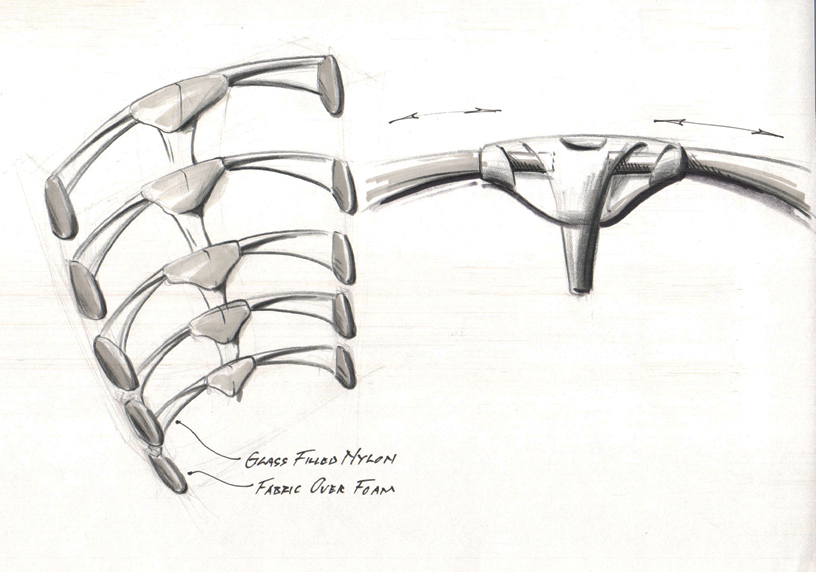

Anatomic chair 2

Glass reinforced Nylon

Molded foam rubber

Anatomic chair 1

Glass reinforced Nylon

Molded foam rubber

Benchable (bench/coffee table)

Bent wood lamination

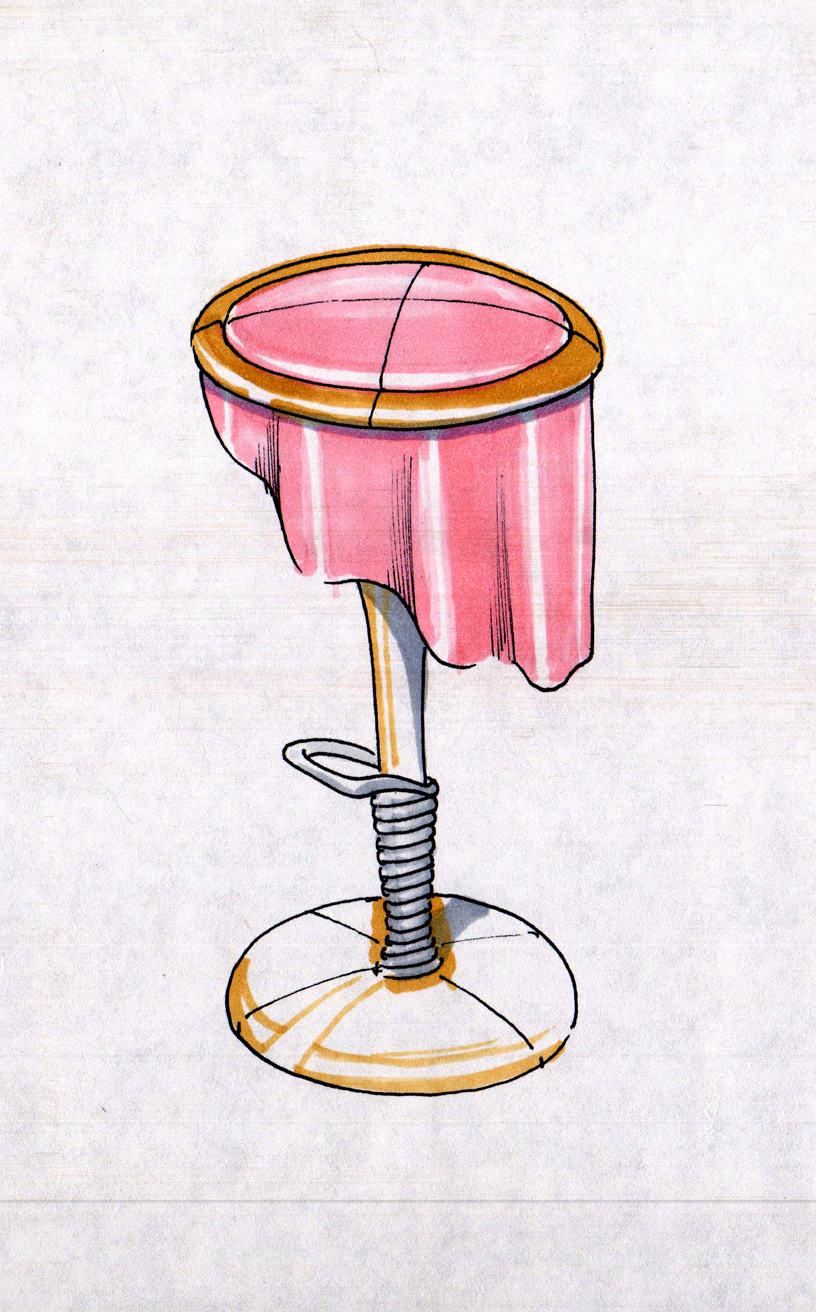

Modular stool 1

Birch plywood, Fabric coated neoprene rubber, fabric

Modular stool 2

Birch plywood, Fabric coated neoprene rubber, fabric

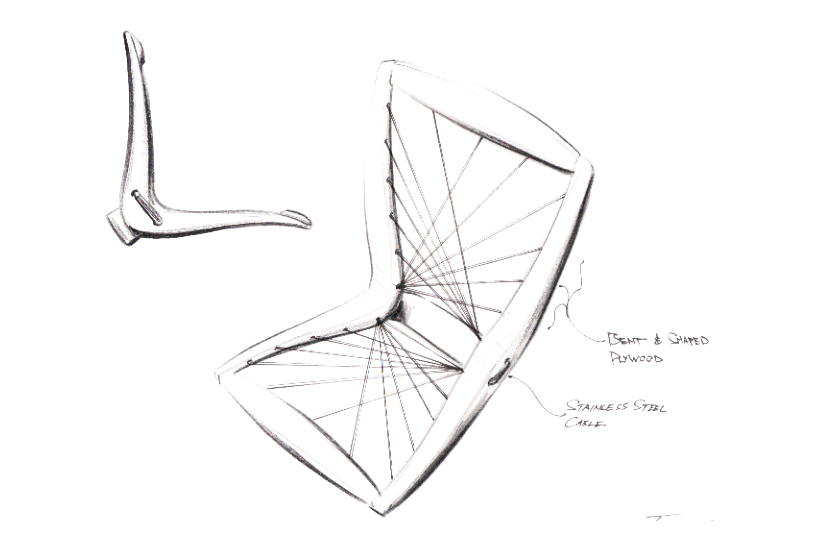

Experiments with wood and wire

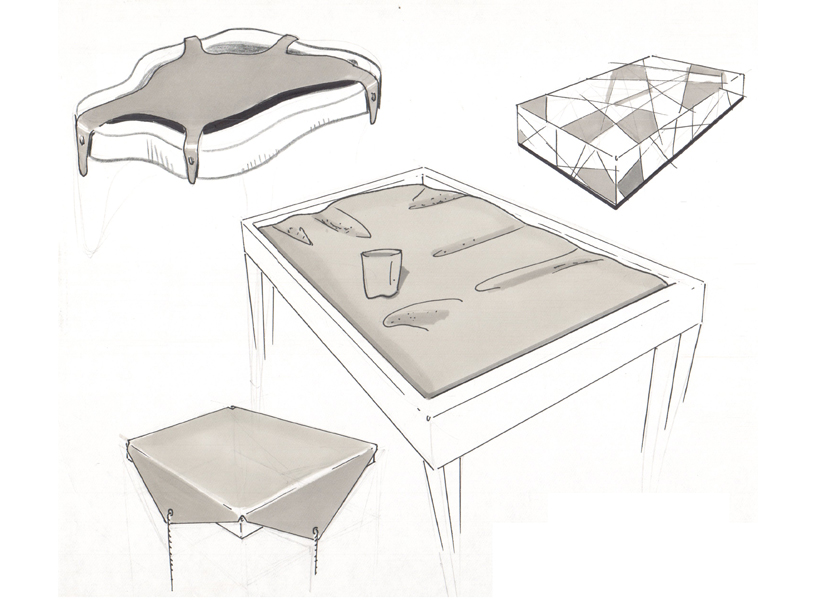

Experiments with alternate coffee table coverings.

Top left: Stretched cowhide (no cows were harmed in the making of this sketch.

Top right: Acrylic pieces

Middle center: ground cork from used wine bottles

Lower left: resin coated ballistic Nylon

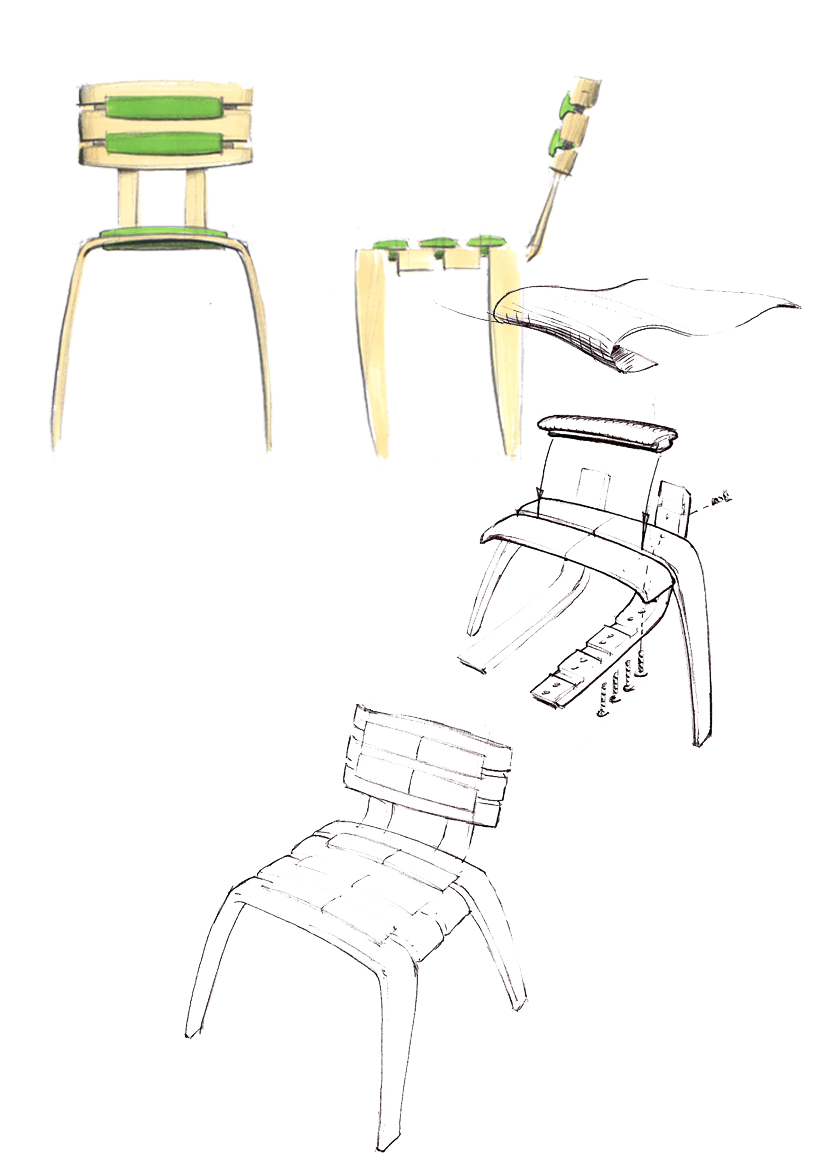

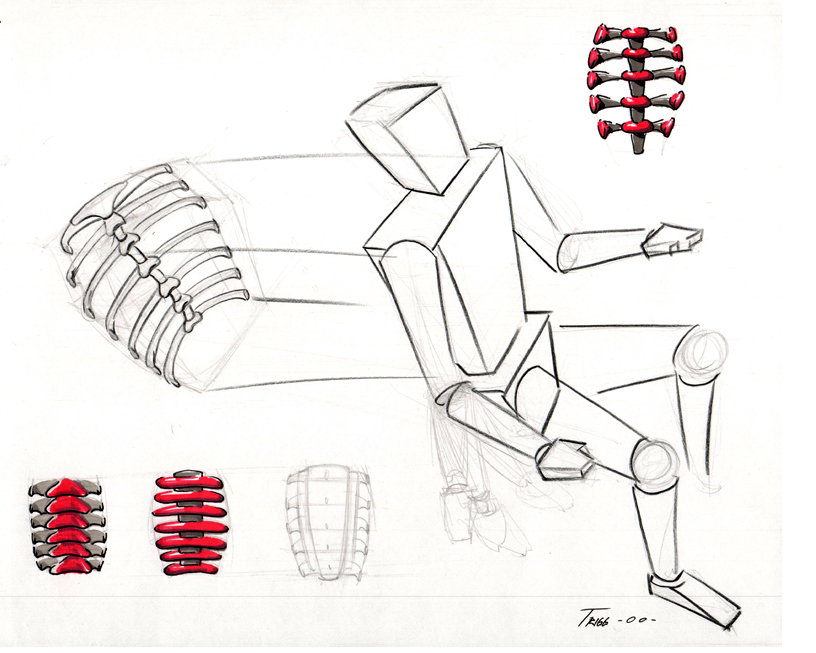

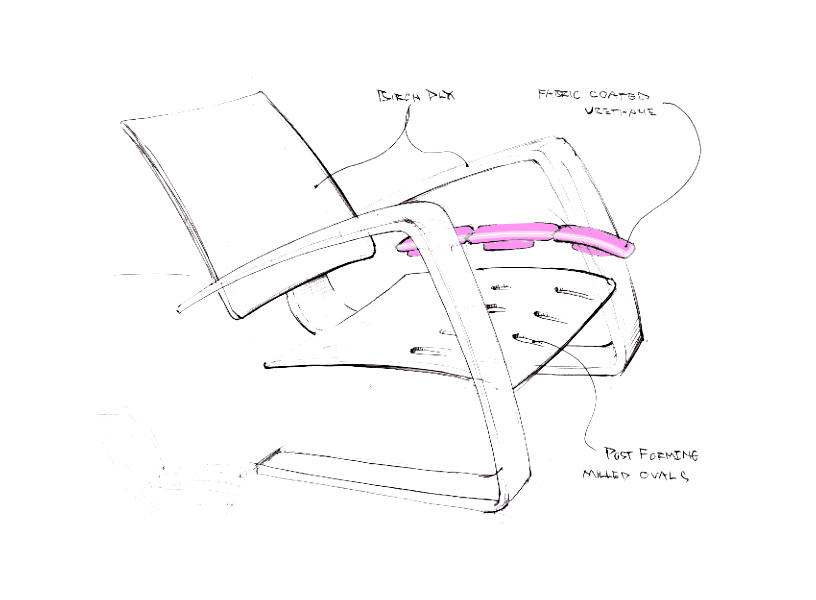

Plug & Play Chair

Bent wood lamination and fabric coated Neoprene rubber.

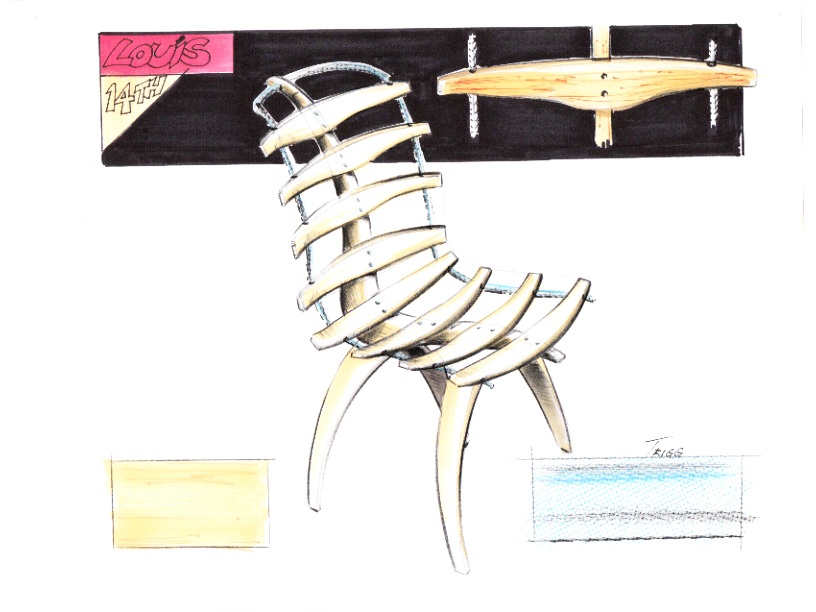

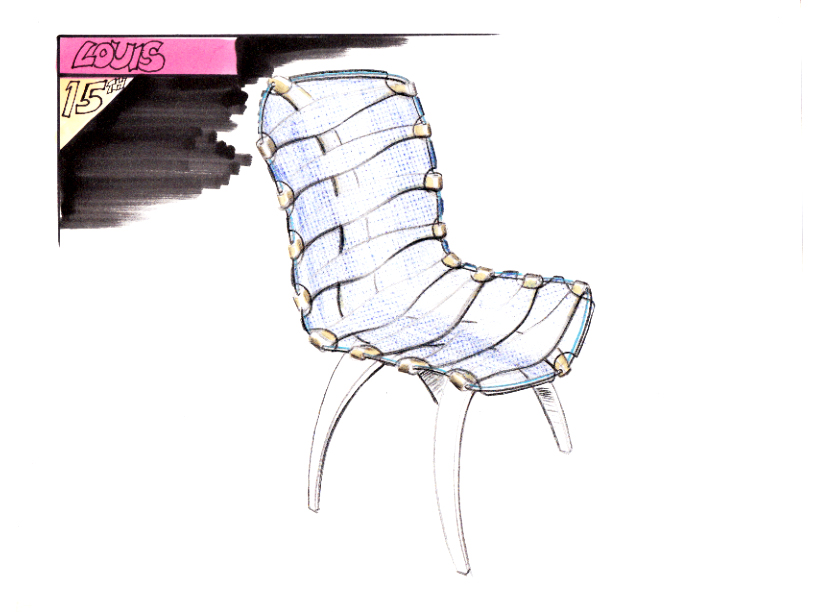

Louis XV

Bent wood lamination, wire and ballistic Nylon.

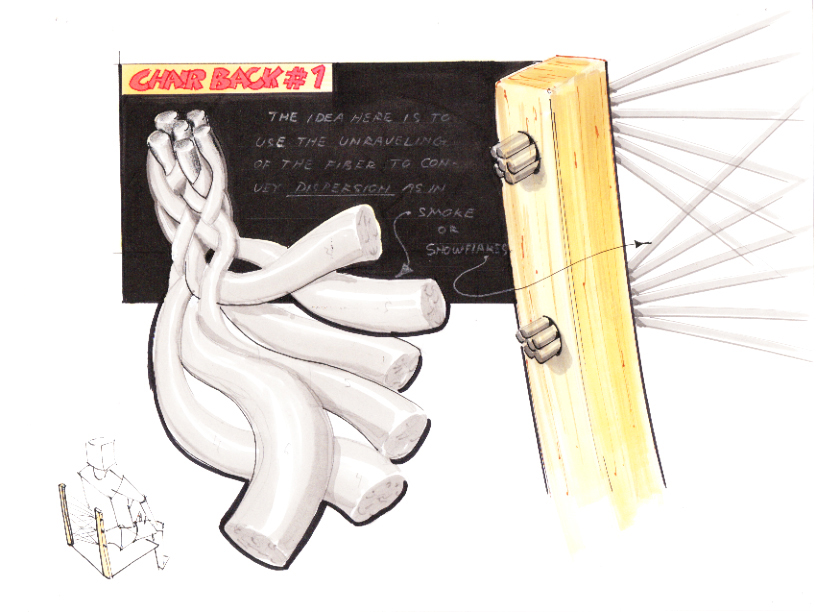

Suspension bridge chair detail

Wood and wire

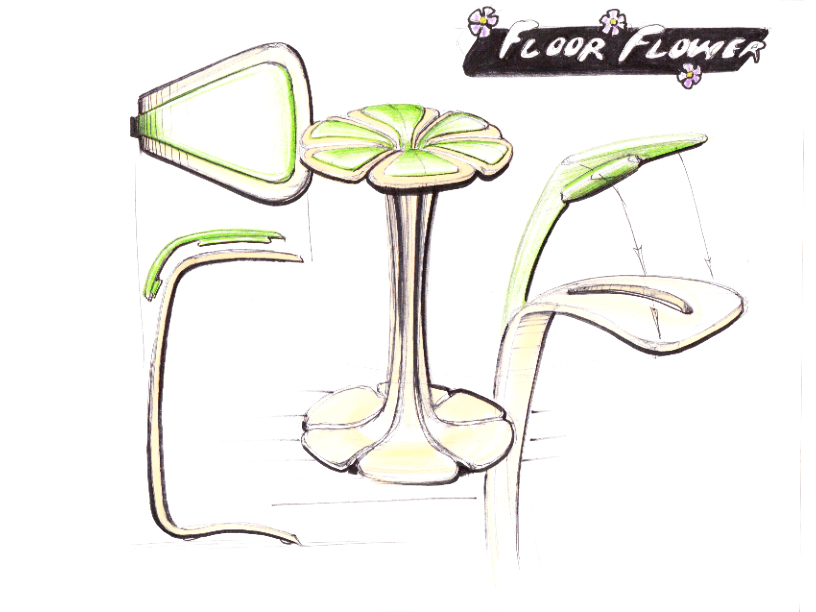

Floor Flower

Bent wood lamination, neoprene foam.

This chair is an experiment in taking the baryl chair concept to its limit. Parts are formed and awaiting cutting.

Suspension bridge chair 3.

Bent wood lamination and braided wire.

SunSitter patio chair. Welded, and anodized stainless steel. Painted cast iron legs.