Lathrop is a premier engineering firm with a strong belief in the value of Industrial design. I work closely with the internal engineering, optics and manufacturing teams to make sure that ID's original design intent is realized.

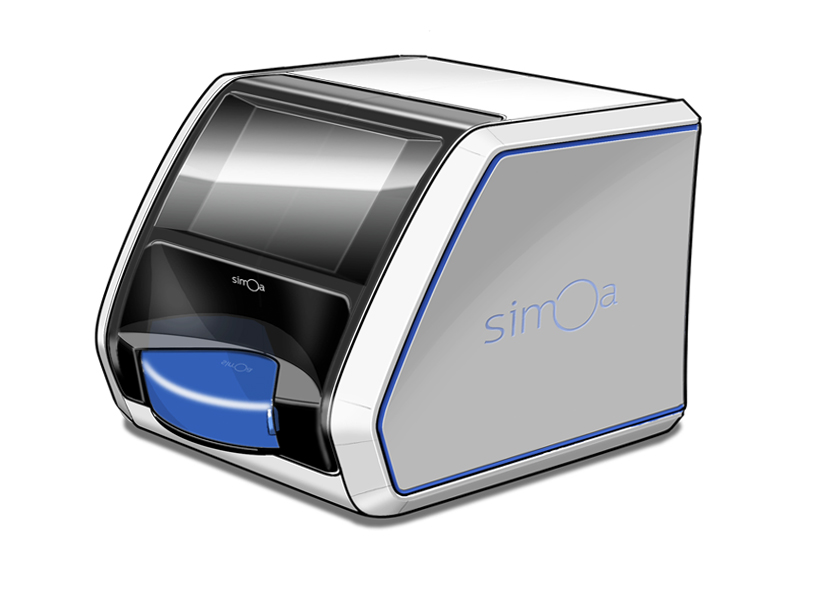

The SR-Plex (left) allows researchers access to ultra-sensitive biomarker detection capabilities in a compact affordable system. The original requirements were for a huge 3' X 5' box that I was sure the customer wouldn't like, so I quickly created and sent the customer a foam core box of those dimensions to get them to rethink the possibilities. They did.

I then followed up with a form study model shown above to be sure they were on track with the design before investing in tooling. My design for the skins consists of only 6 parts to lower cost and ease assembly. I chose gas assist tooling in order to maximize detail and lower cost. the side trim pieces were silicone rubber which have a very economical tooling and COGs profile. All the skins snap on with ball studs with the exception of 2 screws which are necessary in order to fulfill the re safety requirement of having to use a tool to take the first skin off.

Since this was one of Quanterix's first instruments, I created many quick study sketches using their branding guidelines and customer studies to find a look that was appropriate for their category. Ultimately the design below was chosen but the one to the left was a close runner up.

My final sketch of the approved concept before going into CAD.

I created all initial CAD using the master model technique in SolidWorks in order to have all parts update as the final dimensions were being roughed in for component fit with engineering. I also worked with engineering to execute a custom sheet metal frame and cast base which greatly simplified assembly in production.