At D2M, we were asked to take a raw working prototype that used a new solid state vaporizing technology and productize it for the home health market. Sounds easy right?The head marketer from Vapore told us to , "Just make it look cool". I interpreted that into creating a feel for the product that was right for the user. In addition, the product also had to be safe, reliable and easy to use. Another important fact was 50% of purchases were to be used by mothers for their children.

There were a ton of technical risks to be considered when changing the design. This was a plug-in device that contained water that was held by children.

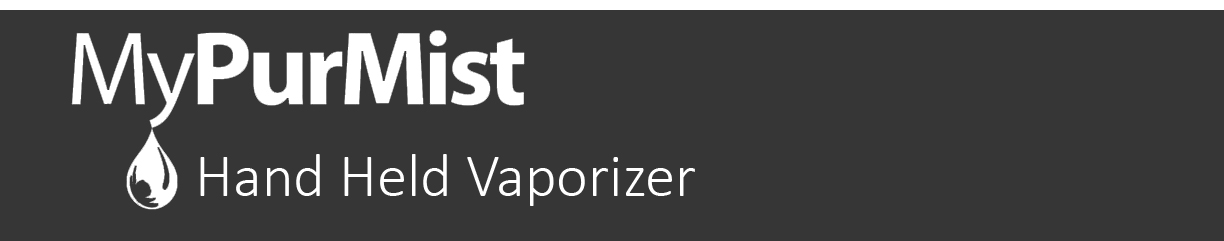

I worked closely with the engineering team to make sure the new industrial design did not fight the technical constraints, but rather helped solve or improve some some, such as water placement and air flow by a more efficient positioning of critical components such as fan and water reservoir.

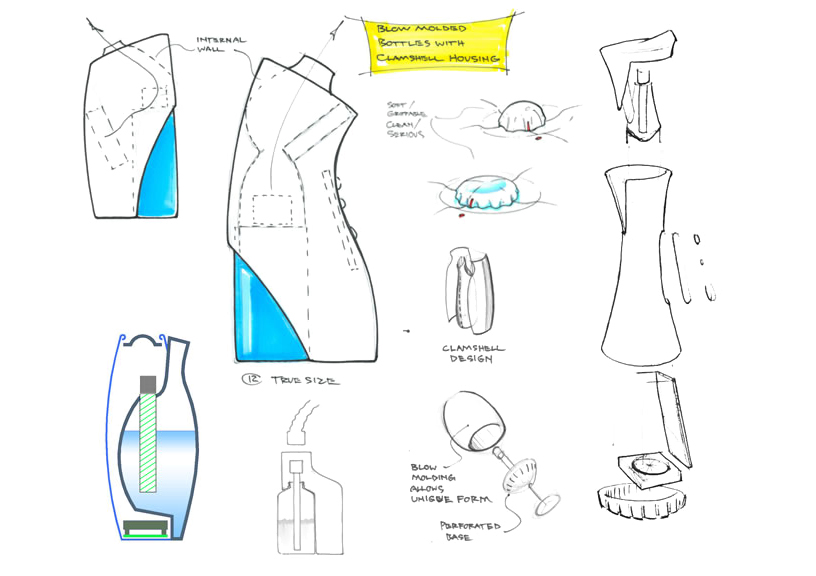

To be honest, the design team was stuck in somewhat of a loop as we went round and round trying to tackle all the issues simultaneously.

Management even brought in an outside industrial design "expert" from Germany who was to save the day. That effort bombed with the client.

I sketched my head off and built quite a few prototypes during this stage.

What I think broke the cycle logjam was my adherence to an iconic forms that were understood by all that kept the major components in the correct position already proven to work.

The vase/glass (image above) won out but I had to make sure the form had was thin enough to hold and point the user to where it should be held for consistent and safe use.

I created all the external and internal forms using Alias and worked with the staff mechanical engineer to finish it off in SolidWorks.

I knew the form and mechanicals were sound, but there was still some doubt, not having buy-in from the sponsor and users. Knowing that, I recommended photo realistic appearance models be made (shown left) to accurately demonstrate form, materials and finishes, which were essential to the experience of this product.

After that, it was pretty clear sailing but there were still ton's of technical issues to be worked out for manufacture. I continued to work with the client to assure that design intent was maintained.

I feel really good about the choices I made for this design. The resulting product is helping a lot of people. The testimonials and the reviews have been great. This product is available with major retailers nationwide now.